Oak Hill Marine Design

Naval Architecture ~ Marine Design ~ Manual and Computer Drafting Services

Russell 26 - Lofted Hull and Construction Patterns

We had lofted two hulls for Russell Boatworks on Great Cranberry Island, so we weren't surprised to be asked if we were interested in lofting another. However, this situation was quite different. This time the hull was nothing like what we'd done before and the boat was to be built in Belize, by local fishermen. Kevin Russell, the yard's owner, had been working with the fishermen in one village to develop a design similar to their current fiberglass boats, which they could build easily from local timber. Kevin had carved a wooden half model, cut it in sections at the stations, and taken sections off it for a rough Lines Plan. With that and the half model we began work.

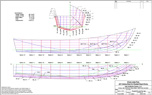

We modeled the hull with four main surfaces - topsides, chine, bottom, and curved transom. When we were satisfied with the shape, we exported sections to our CAD software, rescaled them to match the lines, printed them out, and checked them against the model lines on a light table. It took several tries to create a shape that satisfied the designer. We then added interior surfaces for planking thicknesses and cut those with sections for creating mold patterns.

We created full-size patterns, plotted on Mylar, for each mold, showing the inside and outside of the strip-plank construction, keel section, and gunwale. We also had full-size patterns plotted for the stem and keel, including the locations of the rabbet, back rabbet, and bearding lines. Last we created patterns for the inside and outside of the transom. The latter were to enable the builders to fabricate an accurate curved transom that could be used as the aftermost mold for the boat.

Unfortunately, the patterns were not used, as funds for the actually building project never fully materialized. We regret that we won't find out how well the hull we modeled compares with the local boats. Click here to download the images of Russell 26.